Hydraulic Electro-Pump Units with Fixed Flow

Hydraulic H.F. Units

Hydraulic Electro-Pump Units with Fixed Flow units are mainly designed for large pleasure boats, fishing and work crafts. Owing to a very strong construction, large oil tanks, high reliability of the pumps and distributors and to the easily accessible external mounting of elements connected with flexible tubes, these devices are the leaders on the market in the field of hydraulic electro-pump units.

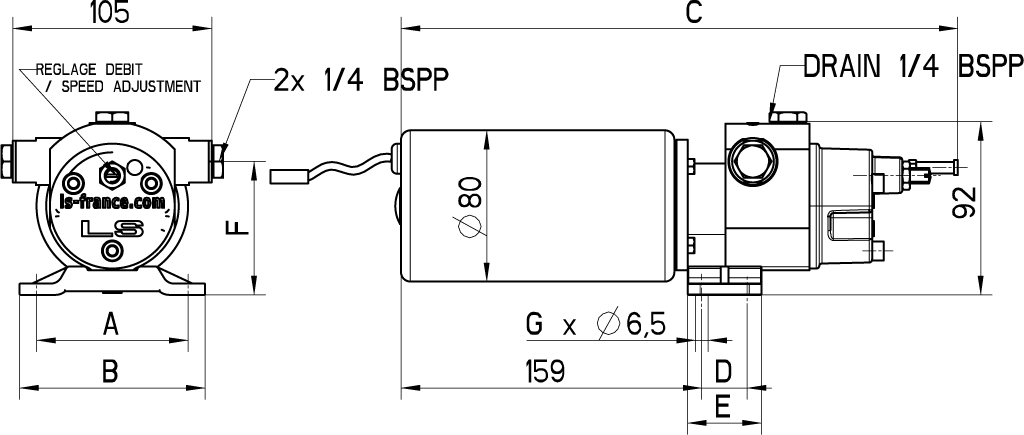

| Tank volume | Flowrate Weight | A | B | C | C | |

|---|---|---|---|---|---|---|

| 2200190 HF 1-2.5 | 10 litres | 2,5 l/mn | 750 | 460 | 220 | 125 |

| 2.65 US gall | 35 kg | 29 (17/32) | 18 (7/64) | 8 (5/8) | 4 (59/64) | |

| 2200148 HF 1-3 | 10 litres | 3 l/mn | 750 | 460 | 220 | 125 |

| 2.65 US gall | 35 kg | 29 (17/32) | 18 (7/64) | 8 (5/8) | 4 (59/64) | |

| 2200149 HF 1-4 | 10 litres | 4 l/mn | 750 | 460 | 220 | 125 |

| 2.65 US gall | 35 kg | 29 (17/32) | 18 (7/64) | 8 (5/8) | 4 (59/64) | |

| 2200150 HF 1-6 | 25 litres | 6 l/mn | 750 | 560 | 270 | 225 |

| 6.62 US gall | 45 kg | 29 (17/32) | 22 (3/64) | 10 (5/8) | 8 (7/8) | |

| 2200151 HF 1.9-9 | 10 litres | 9 l/mn | 750 | 560 | 270 | 225 |

| 6.62 US gall | 57 kg | 29 (17/32) | 22 (3/64) | 10 (5/8) | 8 (7/8) | |

| 2200195 HF 1.9-11 | 10 litres | 11 l/mn | 770 | 560 | 270 | 225 |

| 6.62 US gall | 57 kg | 30 (5/16) | 22 (3/64) | 10 (5/8) | 8 (7/8) | |

| 2200955 HF 3-15 | 50 litres | 15 l/mn | 810 | 785 | 270 | 450 |

| 13.2 US gall | 61 kg | 31 (57/64) | 30 (29/32) | 10 (5/8) | 17 (3/8) | |

| 2200562 HF 3-18 | 10 litres | 18 l/mn | 810 | 785 | 270 | 450 |

| 13.2 US gall | 62 kg | 31 (57/64) | 30 (29/32) | 10 (5/8) | 17 (3/8) | |

| 60 bars maximum pressure – Note : Standard 24 VDC. Other voltages upon request | ||||||