The Theory Behind Common Rail Engines

The Nanni Diesel models, the T4.165, T4.180 & T4.200hp are based on common rail Toyota blocks from their rugged 4×4 automotive sector.

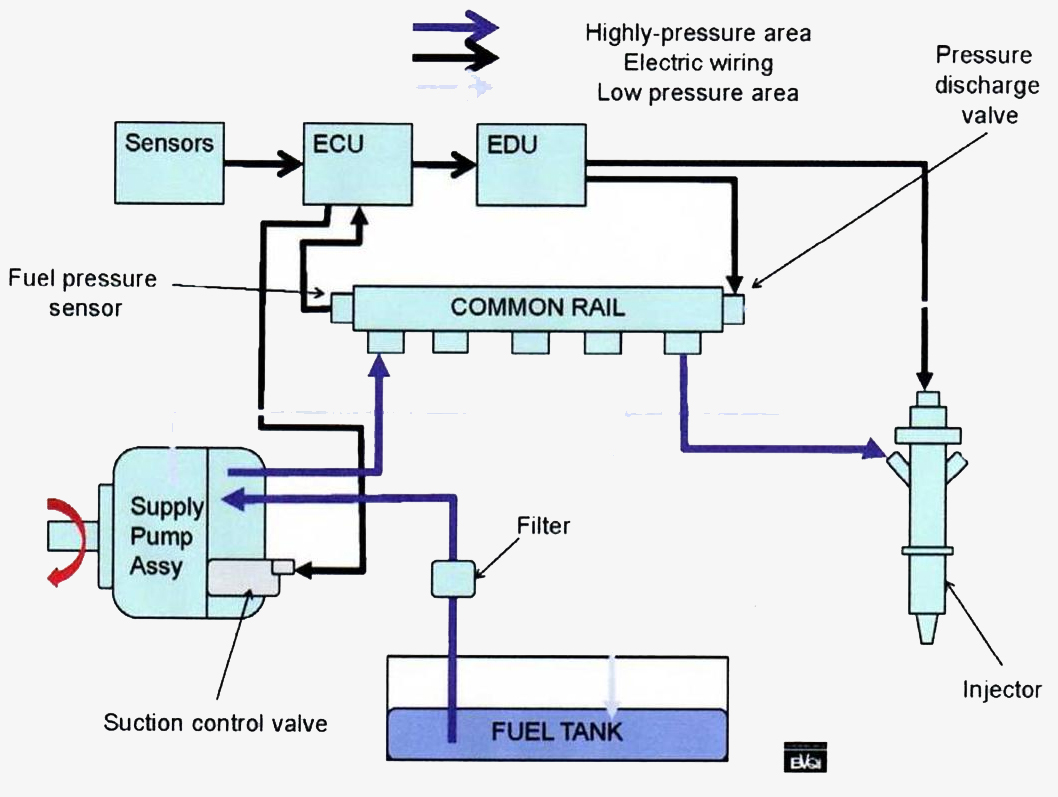

The common rail system uses high-pressurised fuel for improved fuel economy and provides robust engine power, while reducing noise and vibration.

The system stores fuel in the common rail, which has been pressurised and supplied by the supply pump. By storing fuel at high pressure, the common rail can provide fuel at stable fuel injection pressure, regardless of boat speed or engine load.

The ECU (Electronic Control Unit) provides an electric current to the solenoid valve in the injector, which regulates the fuel injection timing and volume, and also monitors the internal fuel pressure of the common rail using the fuel pressure sensor. The ECU regulates the supply pump to supply the fuel necessary to obtain the target fuel pressure.

In addition, this system uses two way valves (TWV) inside the injector to open and close the fuel injection. Therefore, both timing and fuel injection volume can be precisely regulated by the ECU. The common rail system gives two split fuel injections. In order to soften combustion shock, this system performs ‘pilot injection’ as the subsidiary prior to the main fuel injection. This helps to reduce marine engine vibration and noise.