Coolant: The importance of changing coolant on a marine engine

Coolant, also often referred to as antifreeze, or ‘fresh’ water, has an important job in keeping your engine cool.

🔹 1. Prevents Overheating Under Heavy Load

Marine engines often operate at higher loads for longer periods than automotive engines.

Old or degraded coolant loses its efficiency, making it harder to maintain stable temperatures and increasing the risk of overheating, cracked cylinder heads, or complete engine failure at sea.

🔹 2. Protects Against Corrosion & Saltwater Exposure

Most inboard marine engines use a closed-loop cooling system (coolant inside the engine, seawater in the heat exchanger).

Coolant contains anti-corrosion additives which protect the block, cylinder head, and heat exchanger.

When neglected, coolant becomes acidic and accelerates internal corrosion, especially in salty, humid marine environments.

🔹 3. Prevents Scale & Blockage in Heat Exchangers

Old coolant encourages scale deposits and rust flakes that can block narrow passages or heat exchangers.

This restricts heat transfer and can cause dangerous localised hot spots inside the engine.

🔹 4. Maintains Freeze & Boil Protection

In colder climates, degraded coolant may lose antifreeze protection, leading to cracked engine blocks during winter lay-up.

In hot conditions, fresh coolant prevents boiling under heavy load, ensuring stable operating temperatures.

🔹 5. Extends Water Pump & Seal Life

Coolant also lubricates the circulating pump and seals.

When it breaks down, acidity attacks seals and pump bearings, leading to leaks or premature pump failure.

🔹 6. Prevents Electrolysis Damage

Marine environments increase the risk of electrolysis and galvanic corrosion.

Old, electrically conductive coolant accelerates internal corrosion of the engine block, heat exchanger, and aluminium components.

🔹 7. Extends Overall Engine Life

Regular coolant flushes keep the engine running at the correct temperature, reduce corrosion, and prevent costly failures.

For boats, this is not simply maintenance — it’s essential risk management at sea.

✅ Maintenance Tip:

Marine engine manufacturers recommend flushing and replacing coolant every 2–3 years, even if engine hours are low, as marine conditions accelerate coolant breakdown.

Draining the coolant on a Nanni engine is straightforward. Here’s a simple process you can follow (but always double-check your specific engine’s manual, as details can vary):

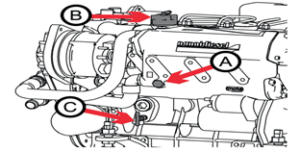

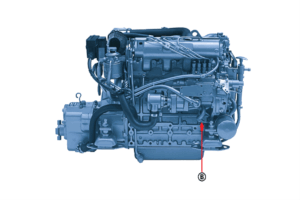

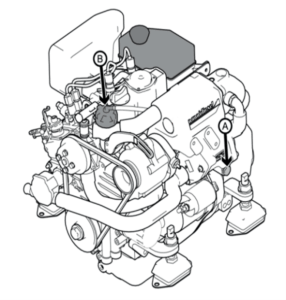

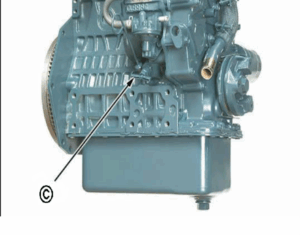

- Locate the drain points:

- Most Nanni engines have a drain plug or drain cock on the engine block.

- There may also be one on the heat exchanger.

- Open the drain taps or remove bungs and allow the coolant to flow out completely. If there’s no drain plug, remove the lowest hose from the cooling circuit.

- Remove the top filler cap (if fitted) to let air in and help the coolant drain faster.

- Flush with fresh water (optional but recommended) to clear residues before refilling.

- Refit the drain plugs/hoses securely.

- Refill with the correct coolant mix (usually a 50/50 mix of antifreeze and water)

- Bleed air from the system, some engines have bleed points, otherwise run the engine with the pressure cap off until air is removed

- Check for leaks and top up to the correct level.

⚠️ Tip: Always dispose of old coolant responsibly – it’s toxic and shouldn’t go into the bilge or overboard ⚠️

Here is our guide to assist you on some of our NANNI engine ranges of approximate positions of tap / bung locations.

Nanni 2- and 3-cylinder ranges

Nanni 4-cylinder ranges