Proportional Distributors

| Proportional Distributors | |

|---|---|

| Dimensions Drawing |

|

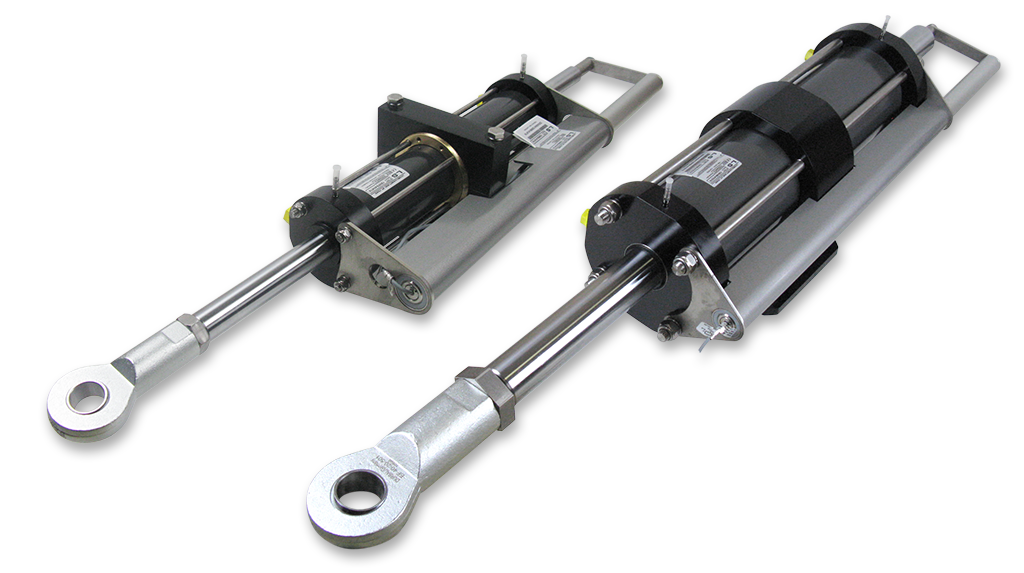

| 2203432 | 10 L Single Proportional Distributors |

| 2203433 | 25 L Single Proportional Distributors |

| 2203434 | 40 L Single Proportional Distributors |

| 2203435 | 10 L Double Proportional Distributors |

| 2203436 | 25 L Double Proportional Distributors |

| 2203437 | 40 L Double Proportional Distributors |

In accordance with the analogue order received by the programmable logic controller, the proportional hydraulic distributor will provide the flow and hydraulic pressure needed to move the cylinder(s) at the speed and to the positions commanded by the steering wheel, the joystick or any other transmitter.

In the case of a double cylinder installation, its independent modules allow for permanent synchronization of the cylinders. The modules are fitted with relief valves which protect the circuit against excessive pressure rise. They feature manual overrides in the event of a loss of power and are protected by a filter with clogging detection alarm. They can be delivered assembled on the equipped tank or separately for on-line installation between the equipped tank and the cylinders.